GET FREE SAMPLES

Please fill this for and we'll get back to you as soon as possible!

After filling in the form, you will receive it

1、Test free samples

2、Pricing & catelog

3、Customized design plan

4、High -level services of one -to -one 24*7 hours

What help can we provide you?

1、Customize production size and parameter formula according to your product style.

2、Industrial experts solve the problem of industrial demand 24*7 online support.

3、Video and pictures of providing actual product shooting.

4、Real factory, support friends all over the world to visit and let you feel at ease.

5、Time to track and feedback in the production link to ensure that customers understand every link of production in production.

6、Super customers can come to China to travel 2-5 times a year for free.

7、Become our customers to enjoy low prices and free samples in the industry.

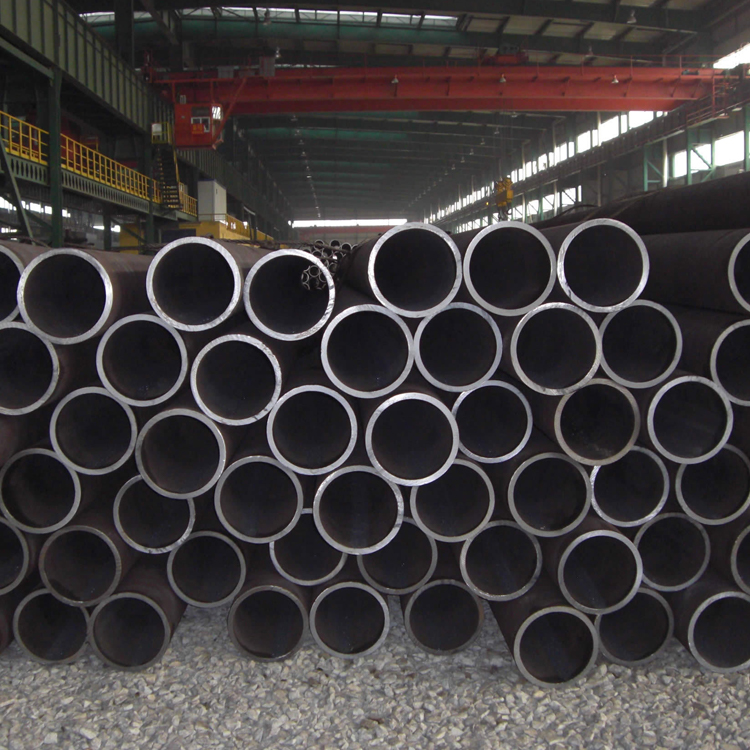

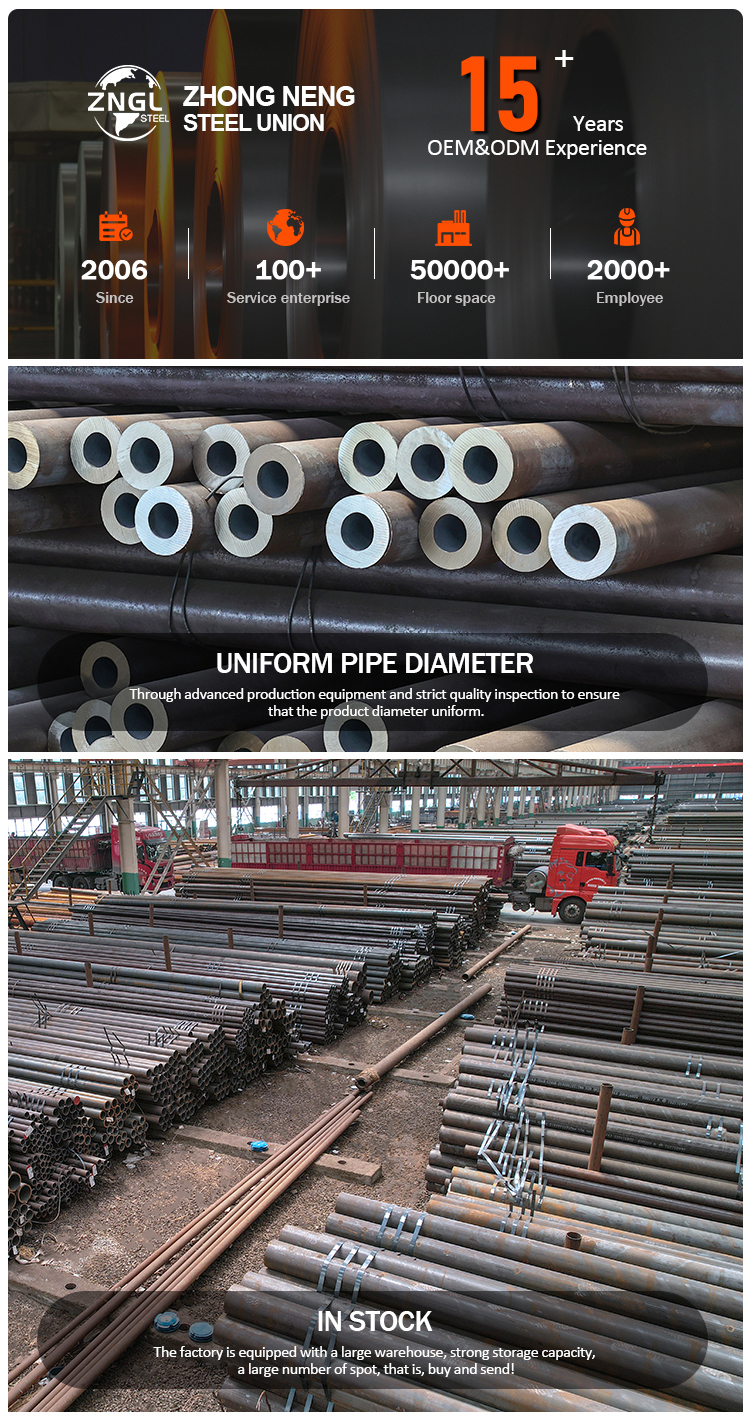

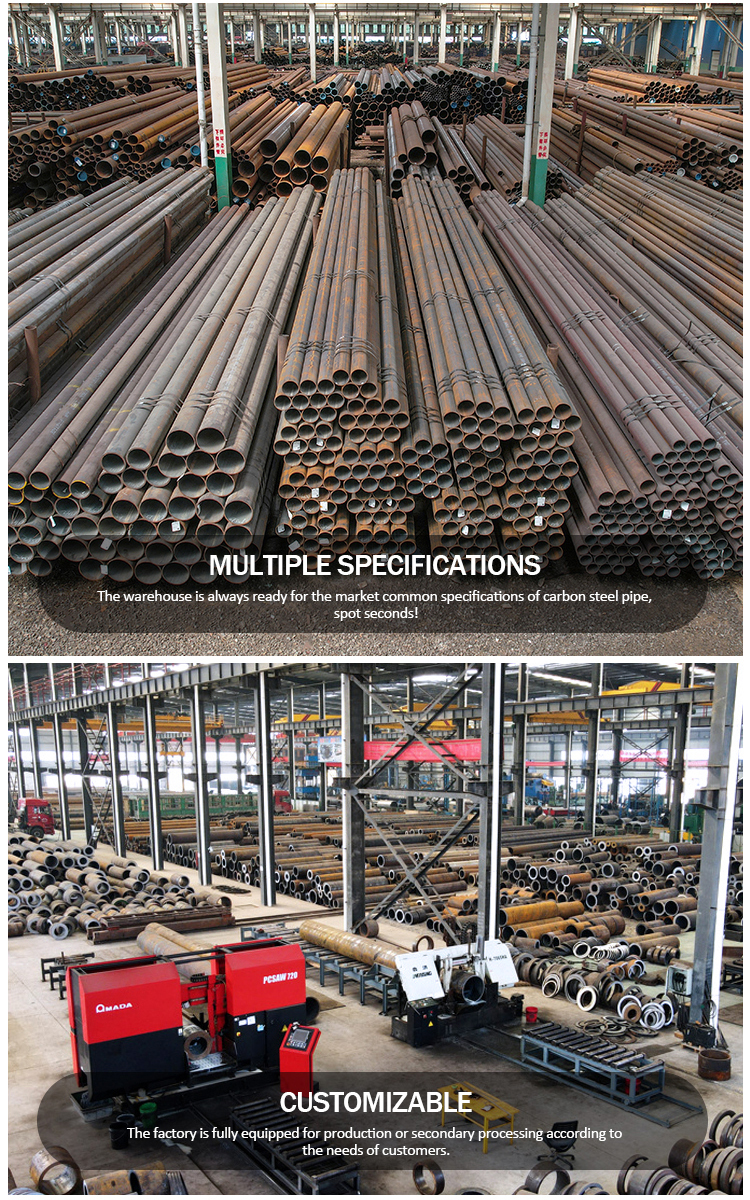

Carbon Steel Round Pipe Wholesale

Brand Name:ZNGL

Place of Origin:China

Tolerance:±5%, ±1%

Processing Service:Welding, Punching, Cutting, Bending, Decoiling

Oiled or Non-oiled:Non-oiled

Invoicing:by theoretical weight

Delivery Time: 7-30 days

Hot-rolled carbon steel pipes can be divided into seamless steel pipes, straight seam steel pipes, spiral steel pipes, and high-frequency welded steel pipes. The hot-rolled carbon steel pipe is made of round pipe as raw material, and the pipe embryo is cut into about 1 meter long wool by cutting machine, and sent to the heating furnace for heating on the conveyor belt. The hot-rolled carbon steel pipes are also fed into the furnace and heated at about 1200 degrees Celsius.

| Grade Comparison | |

| GB | NM300,NM360,NM400,NM450,NM500 |

| SS | HARDNESS400, HARDNESS450, HARDNESS500, HARDNESS600 |

| DIN | XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500 |

| NBN | QUARD400, QUARD450, QUARD500 |

| NF | FORA400, FORA500, Creusabro4800, Creusabro8000 |

| JIS | JFE-EH360 , JFE - EH400 , JFE - EH500 , WEL-HARD400 , WELHARD500 |

| SFS | RAEX400, RAEX450, RAEX500 |

| Grade | |||||

| Chemical Composition ( ≤ ) | NM300 | NM360 | NM400 | NM450 | NM500 |

| C | 0.23 | 0.25 | 0.3 | 0.35 | 0.38 |

| Si | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Mn | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

| S | 0.015 | 0.015 | 0.01 | 0.01 | 0.01 |

| Cr | 0.8 | 1.1 | |||

| Ni | 0.5 | 0.5 | 0.7 | 0.8 | 1 |

| Mo | 0.4 | 0.5 | 0.5 | 0.55 | 0.65 |

| Thickness (mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤70 |

| Tensile strength (MPa) | ≥1000 | ≥1100 | ≥1200 | ≥1250 | -- |

| Elongation A (%) | ≥14 | ≥12 | ≥10 | ≥7 | -- |

| Surface Brinell hardness (HBW) | 270-330 | 330-390 | 370-430 | 420-480 | ≥470 |

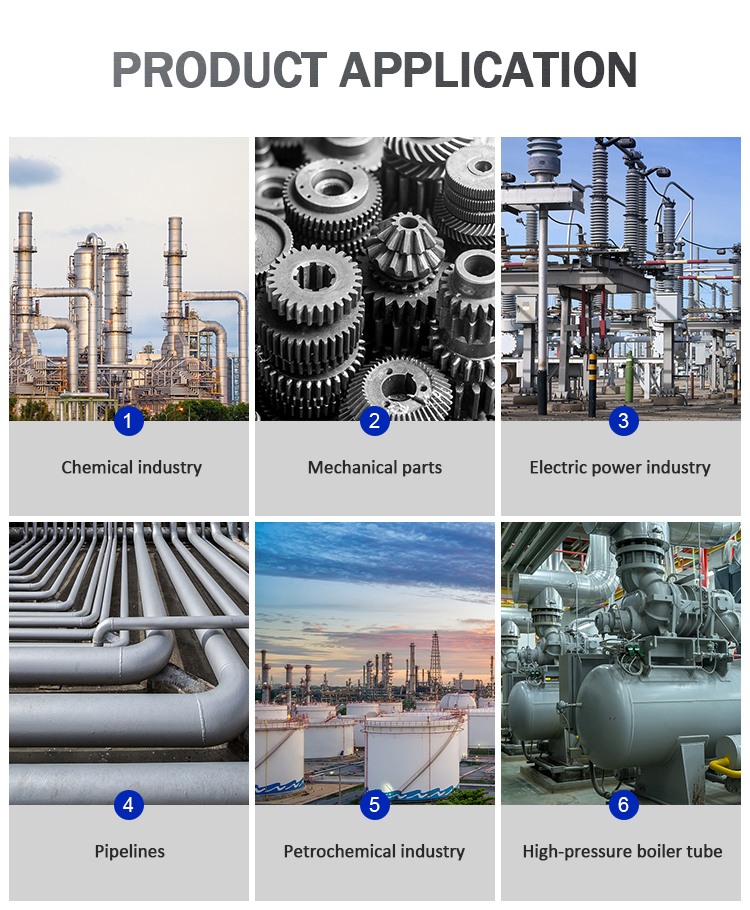

Hot-rolled carbon steel pipe can be used to describe various metal tubular items. The main alloying element of hot-rolled carbon steel pipe is 0.12%-2% carbon. Carbon elements other than chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium and zirconium can be added to obtain respective alloying effects.