GET FREE SAMPLES

Please fill this for and we'll get back to you as soon as possible!

After filling in the form, you will receive it

1、Test free samples

2、Pricing & catelog

3、Customized design plan

4、High -level services of one -to -one 24*7 hours

What help can we provide you?

1、Customize production size and parameter formula according to your product style.

2、Industrial experts solve the problem of industrial demand 24*7 online support.

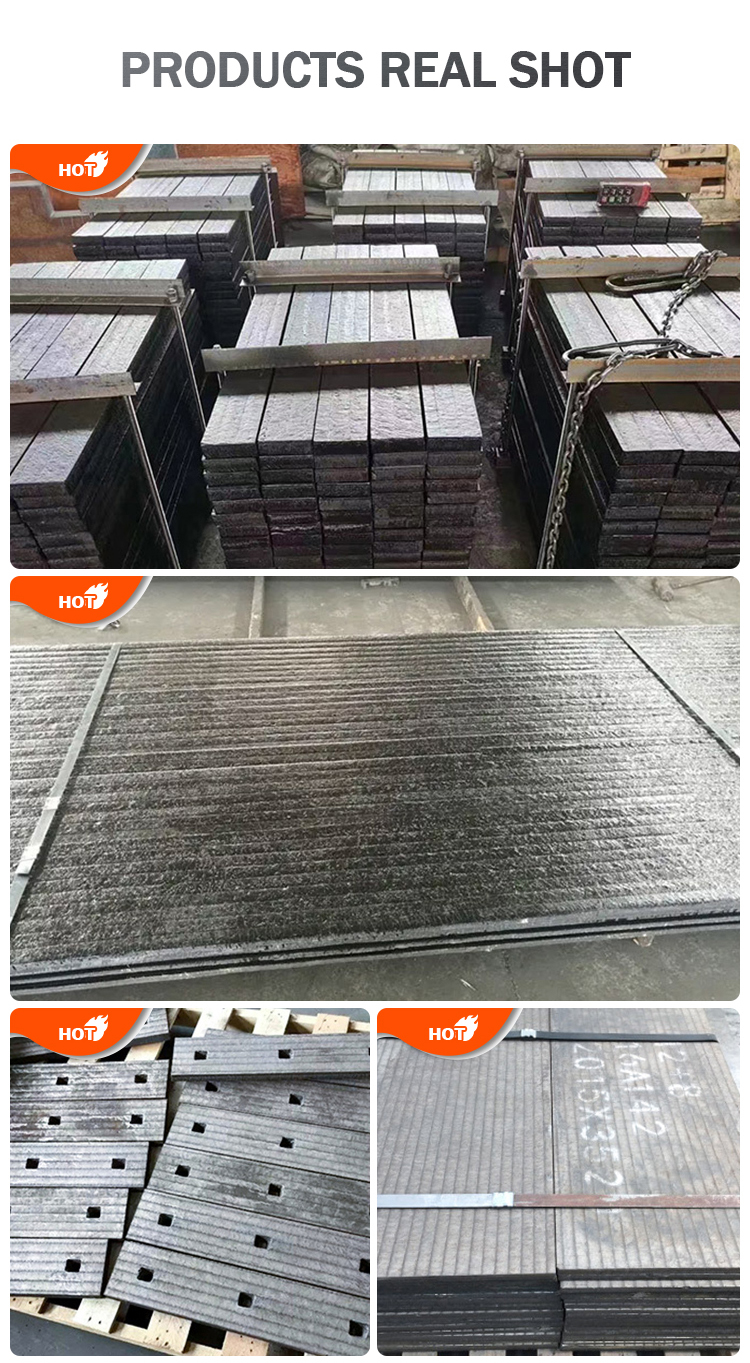

3、Video and pictures of providing actual product shooting.

4、Real factory, support friends all over the world to visit and let you feel at ease.

5、Time to track and feedback in the production link to ensure that customers understand every link of production in production.

6、Super customers can come to China to travel 2-5 times a year for free.

7、Become our customers to enjoy low prices and free samples in the industry.

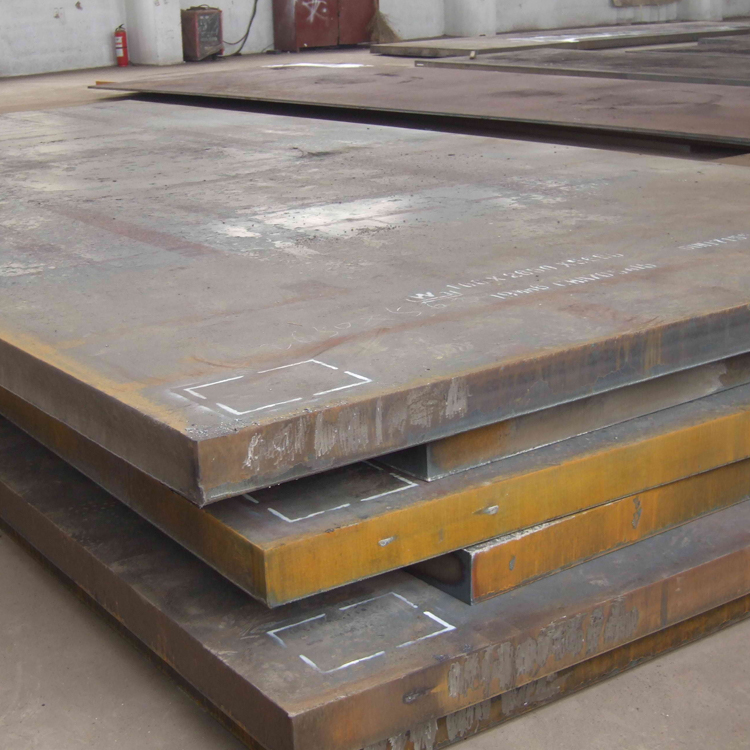

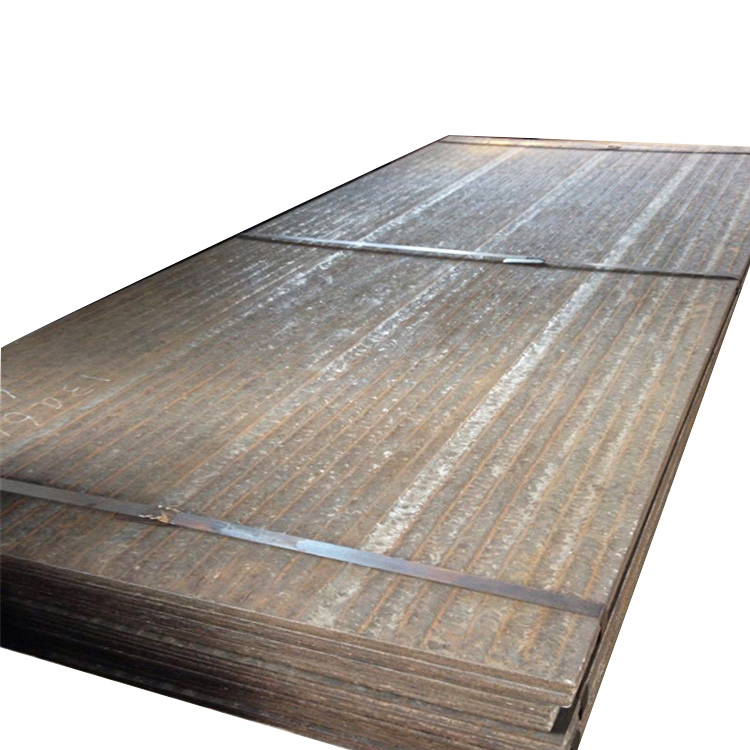

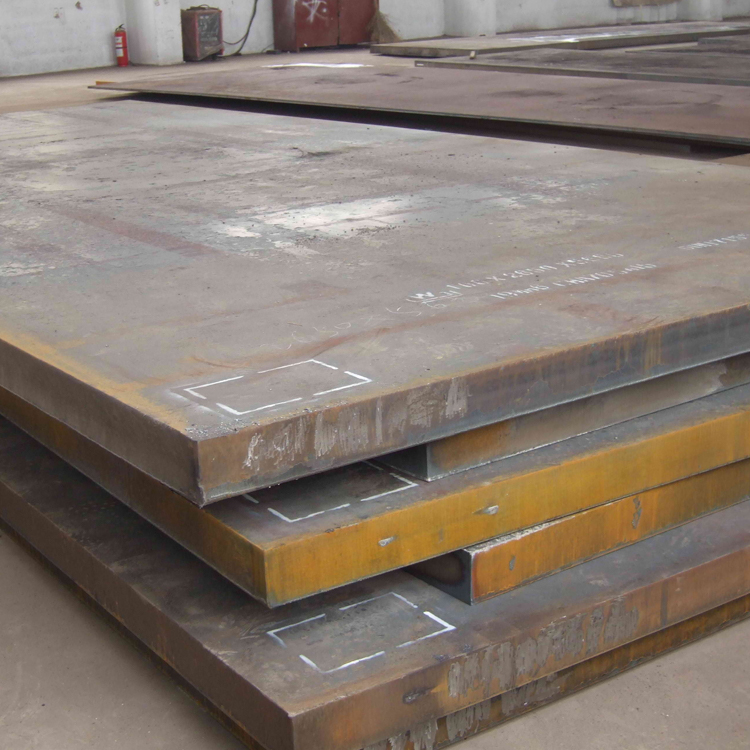

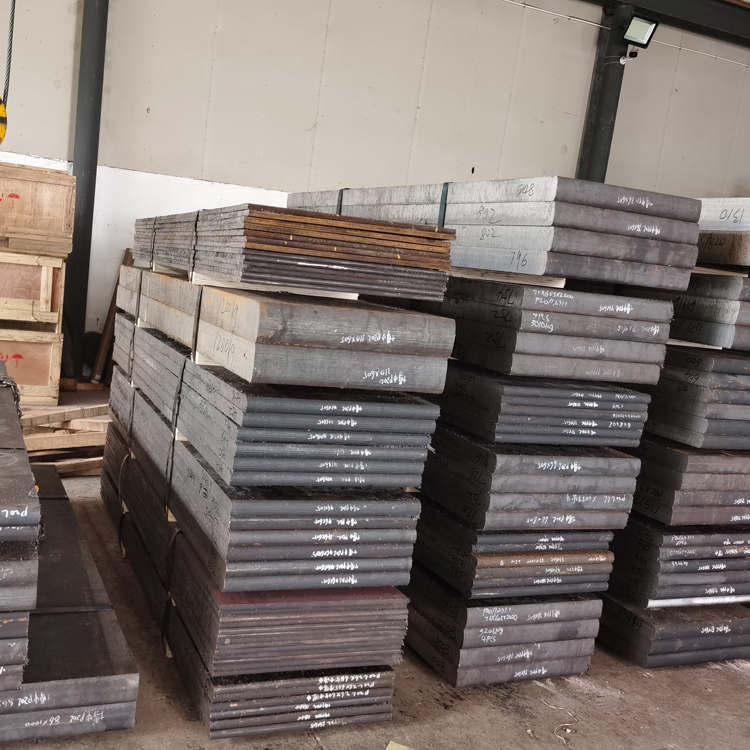

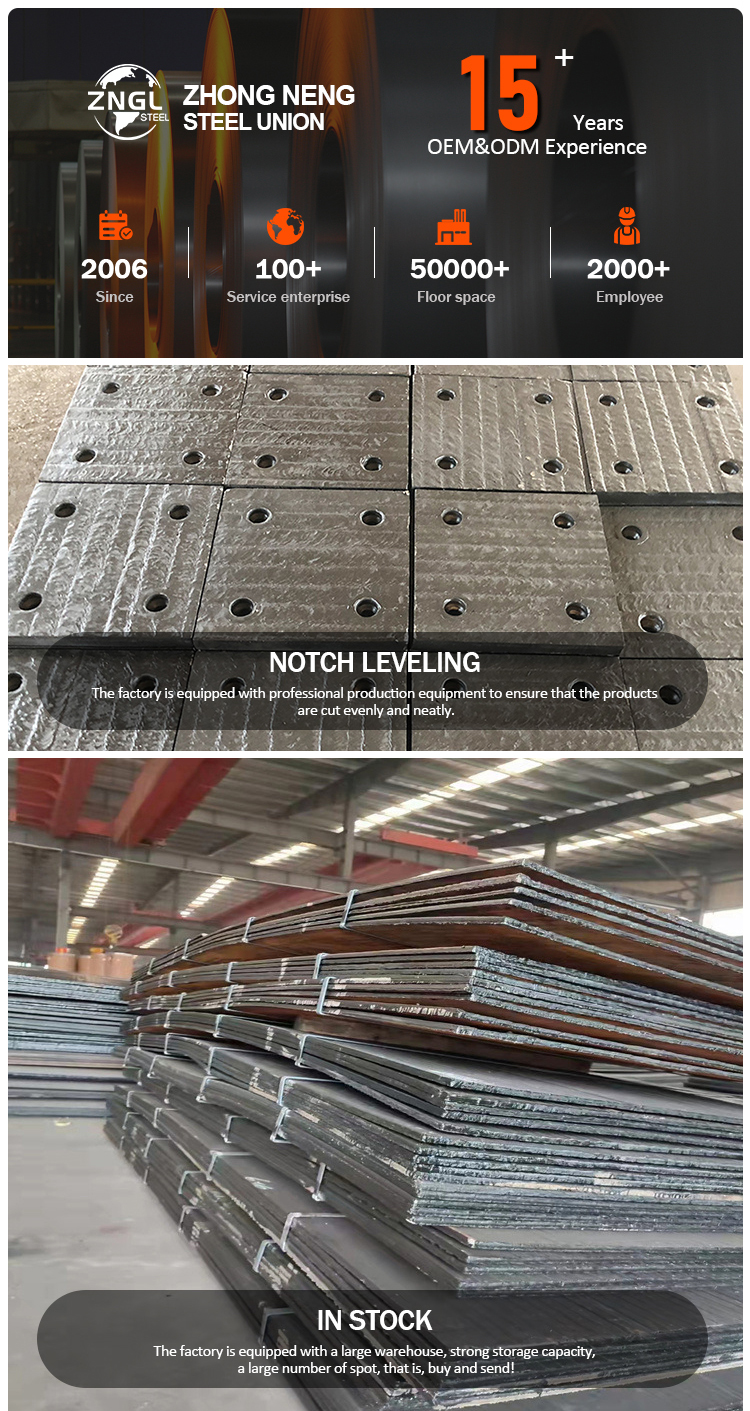

Surfacing Wear Resistant Carbon Steel Plates Stock

Product Name:Surfacing Wear Resistant Carbon Steel Plate

Brand Name:ZNGL

Application:mining machinery Bridges, Buildings

Thickness:3mm-40mm

Standard:AiSi, ASTM, bs, DIN, GB, JIS

Width:600mm-2500mm

Length:2.44-12m , customized, As your requirements

Certificate:ce, ISO9001

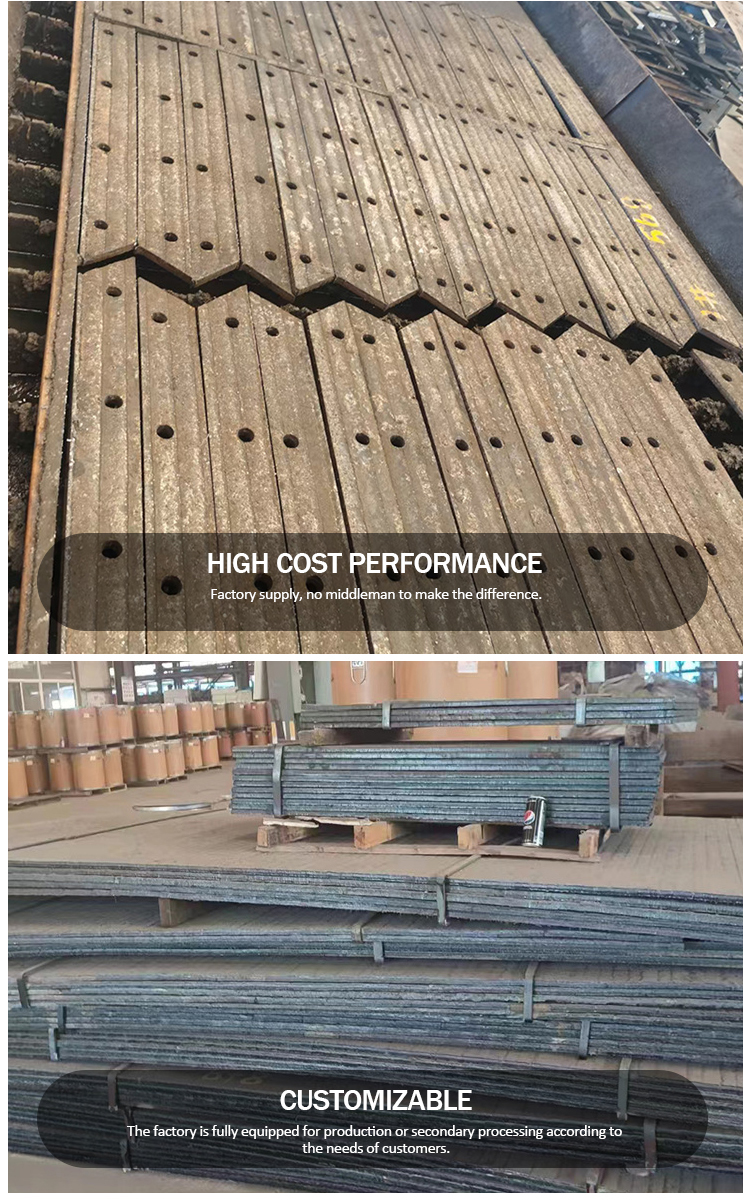

Processing Service:Bending, Welding, Decoiling, Cutting, Punching

Surfacing wear-resistant plate is a kind of wear-resistant plate that can be bent and welded. Due to its high hardness, high strength and high toughness, it is obviously an ideal choice for those occasions with severe wear. The high wear resistance of hardfacing wear plates extends the life of dump truck bodies, buckets of excavators, crushers and similar equipment.

Grade Comparison | |

GB | NM300,NM360,NM400,NM450,NM500 |

SS | HARDNESS400, HARDNESS450, HARDNESS500, HARDNESS600 |

DIN | XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500 |

NBN | QUARD400, QUARD450, QUARD500 |

NF | FORA400, FORA500, Creusabro4800, Creusabro8000 |

JIS | JFE-EH360 , JFE - EH400 , JFE - EH500 , WEL-HARD400 , WELHARD500 |

SFS | RAEX400, RAEX450, RAEX500 |

Grade | |||||

Chemical Composition ( ≤ ) | NM300 | NM360 | NM400 | NM450 | NM500 |

C | 0.23 | 0.25 | 0.3 | 0.35 | 0.38 |

Si | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Mn | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

S | 0.015 | 0.015 | 0.01 | 0.01 | 0.01 |

Cr | 0.8 | 1.1 | |||

Ni | 0.5 | 0.5 | 0.7 | 0.8 | 1 |

Mo | 0.4 | 0.5 | 0.5 | 0.55 | 0.65 |

Thickness (mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤70 |

Tensile strength (MPa) | ≥1000 | ≥1100 | ≥1200 | ≥1250 | -- |

Elongation A (%) | ≥14 | ≥12 | ≥10 | ≥7 | -- |

Surface Brinell hardness (HBW) | 270-330 | 330-390 | 370-430 | 420-480 | ≥470 |

Overlay welding wear-resistant composite plate, the common name is wear-resistant composite steel plate, which is a kind of high wear-resistant composite material. It adopts automatic plate welding equipment to form a hypereutectic high-chromium alloy wear-resistant layer on the steel plate, which becomes a pile Welded high chromium alloy wear-resistant steel plate.

manufacturers supplier company factory mills