GET FREE SAMPLES

Please fill this for and we'll get back to you as soon as possible!

After filling in the form, you will receive it

1、Test free samples

2、Pricing & catelog

3、Customized design plan

4、High -level services of one -to -one 24*7 hours

What help can we provide you?

1、Customize production size and parameter formula according to your product style.

2、Industrial experts solve the problem of industrial demand 24*7 online support.

3、Video and pictures of providing actual product shooting.

4、Real factory, support friends all over the world to visit and let you feel at ease.

5、Time to track and feedback in the production link to ensure that customers understand every link of production in production.

6、Super customers can come to China to travel 2-5 times a year for free.

7、Become our customers to enjoy low prices and free samples in the industry.

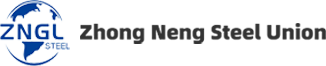

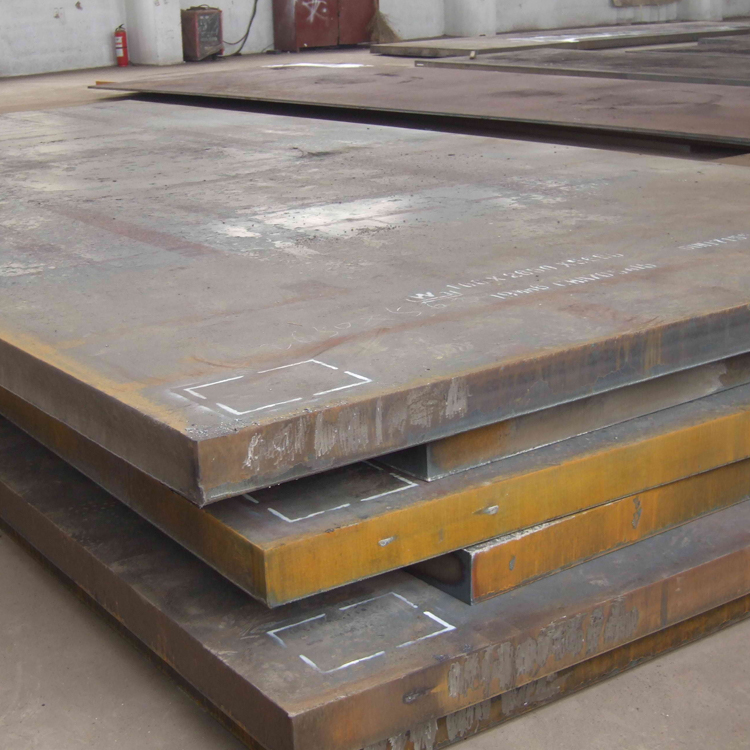

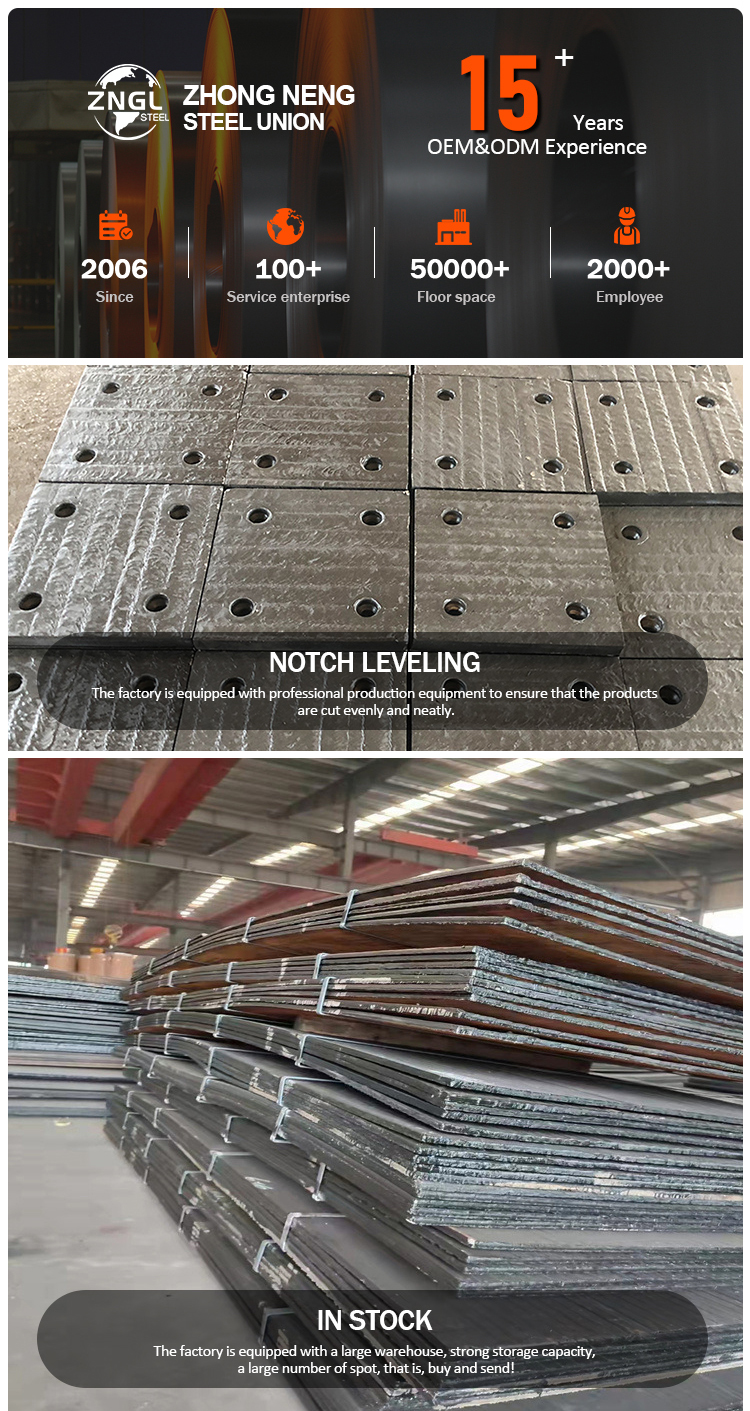

Wholesale Surfacing Wear Resistant Carbon Steel Plates

Product Name:Surfacing Wear Resistant Carbon Steel Plate

Brand Name:ZNGL

Thickness:3mm-40mm

Standard:AiSi, ASTM, bs, DIN, GB, JIS

Width:600mm-2500mm

Material:NM360 400 450 500 550 600

Surface Treatment:hardening and tempering

Edge:Mill Edge Slit Edge

Payment term:TT / LC

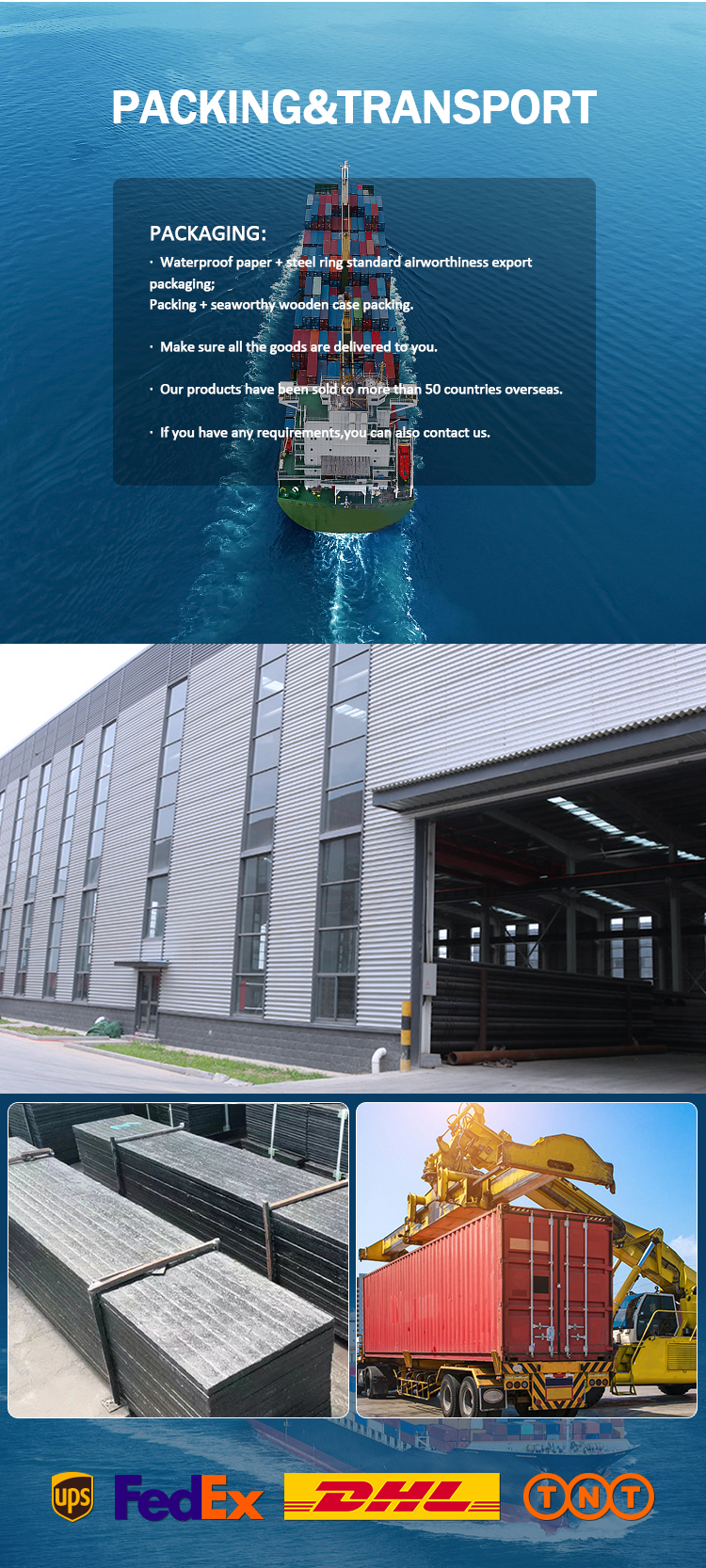

Package:Sea-worthy Package

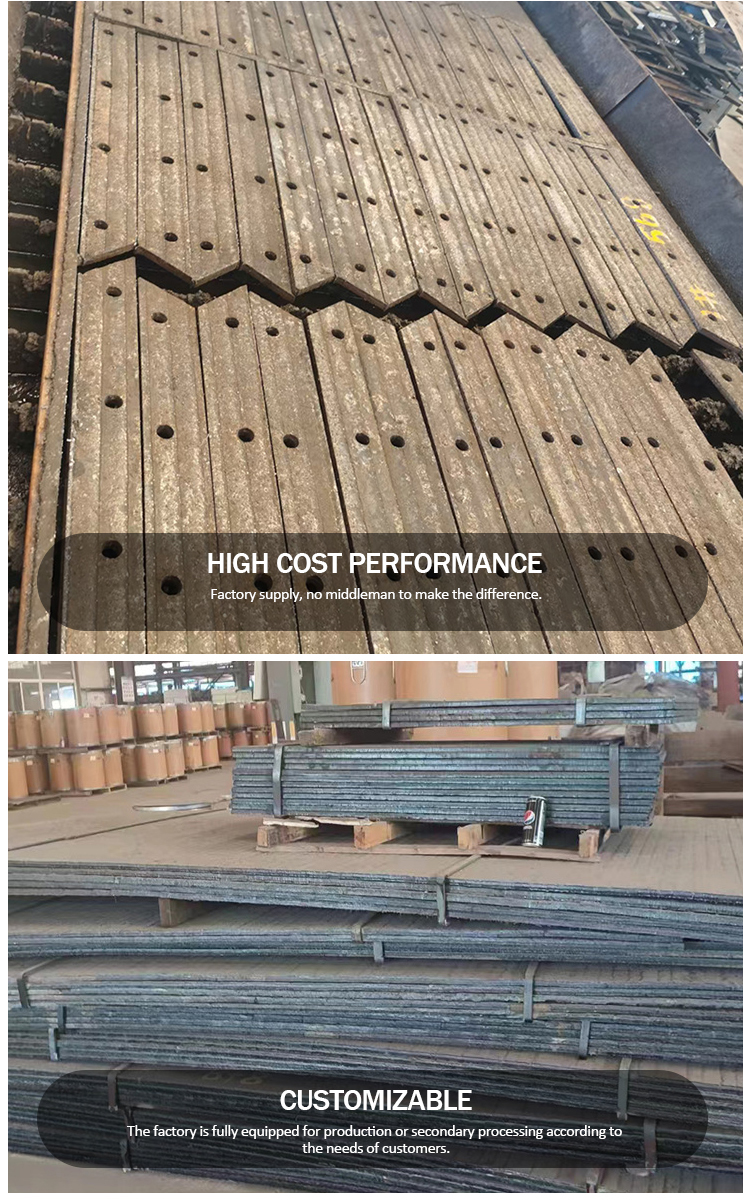

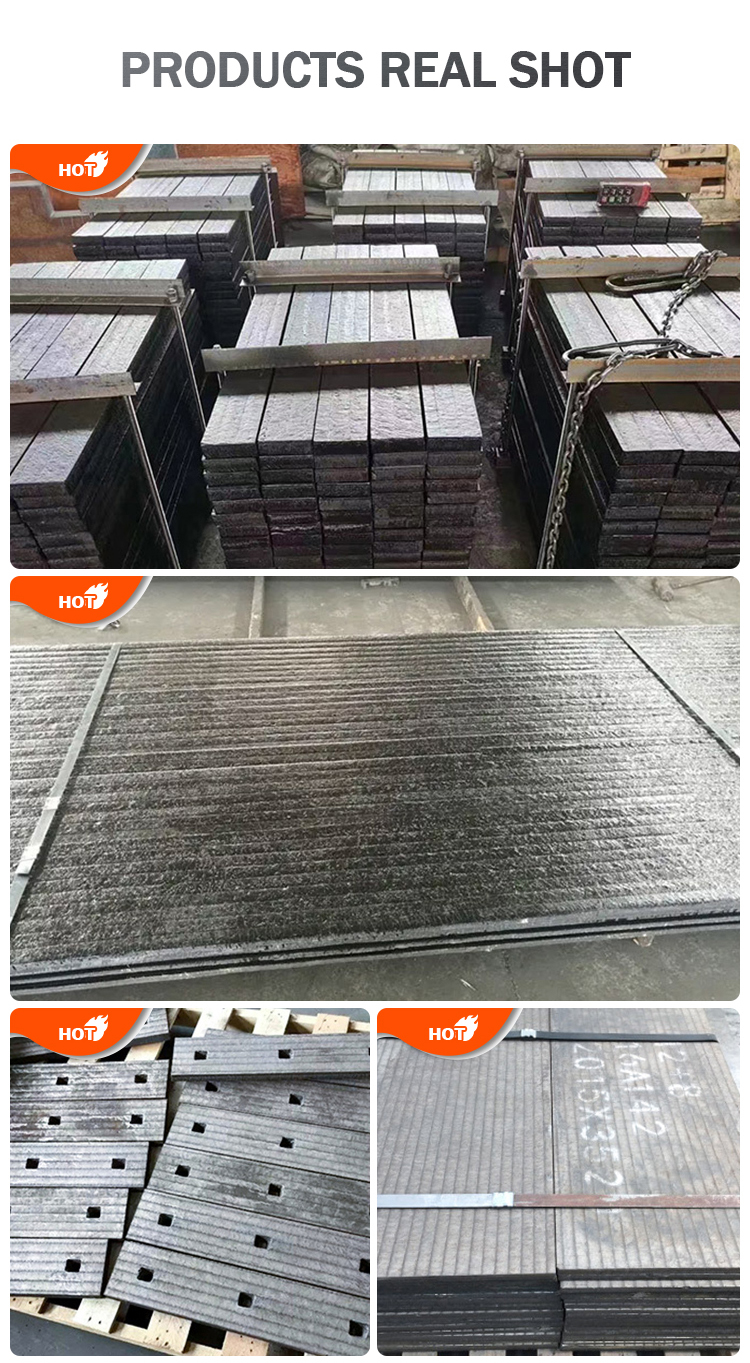

The hardness of the surfacing wear-resistant plate is generally HRC53-60 within 6mm, and the above is HRC56-63. The material of the surfacing wear-resistant plate: divided into general materials and special materials (proposed for wear resistance and high temperature resistance, etc Special requirements), surfacing wear-resistant plate standard plate: a whole plate with a width of about 1.5 meters and a length of about 3 meters, in a flat state. Customized plate for surfacing wear-resistant plate: customized according to the size and shape required by the customer.

Grade Comparison | |

GB | NM300,NM360,NM400,NM450,NM500 |

SS | HARDNESS400, HARDNESS450, HARDNESS500, HARDNESS600 |

DIN | XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500 |

NBN | QUARD400, QUARD450, QUARD500 |

NF | FORA400, FORA500, Creusabro4800, Creusabro8000 |

JIS | JFE-EH360 , JFE - EH400 , JFE - EH500 , WEL-HARD400 , WELHARD500 |

SFS | RAEX400, RAEX450, RAEX500 |

Grade | |||||

Chemical Composition ( ≤ ) | NM300 | NM360 | NM400 | NM450 | NM500 |

C | 0.23 | 0.25 | 0.3 | 0.35 | 0.38 |

Si | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Mn | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

S | 0.015 | 0.015 | 0.01 | 0.01 | 0.01 |

Cr | 0.8 | 1.1 | |||

Ni | 0.5 | 0.5 | 0.7 | 0.8 | 1 |

Mo | 0.4 | 0.5 | 0.5 | 0.55 | 0.65 |

Thickness (mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤70 |

Tensile strength (MPa) | ≥1000 | ≥1100 | ≥1200 | ≥1250 | -- |

Elongation A (%) | ≥14 | ≥12 | ≥10 | ≥7 | -- |

Surface Brinell hardness (HBW) | 270-330 | 330-390 | 370-430 | 420-480 | ≥470 |

Performance of surfacing wear-resistant plate: the yield is more than 800, and the tensile strength is above 1000. NM400 wear-resistant plate is a high-strength wear-resistant steel plate. ) is mainly to provide protection for occasions or parts that require wear resistance, so as to make the equipment last longer, reduce maintenance and shutdown caused by maintenance, and correspondingly reduce capital investment.

manufacturers supplier company factory mills