GET FREE SAMPLES

Please fill this for and we'll get back to you as soon as possible!

After filling in the form, you will receive it

1、Test free samples

2、Pricing & catelog

3、Customized design plan

4、High -level services of one -to -one 24*7 hours

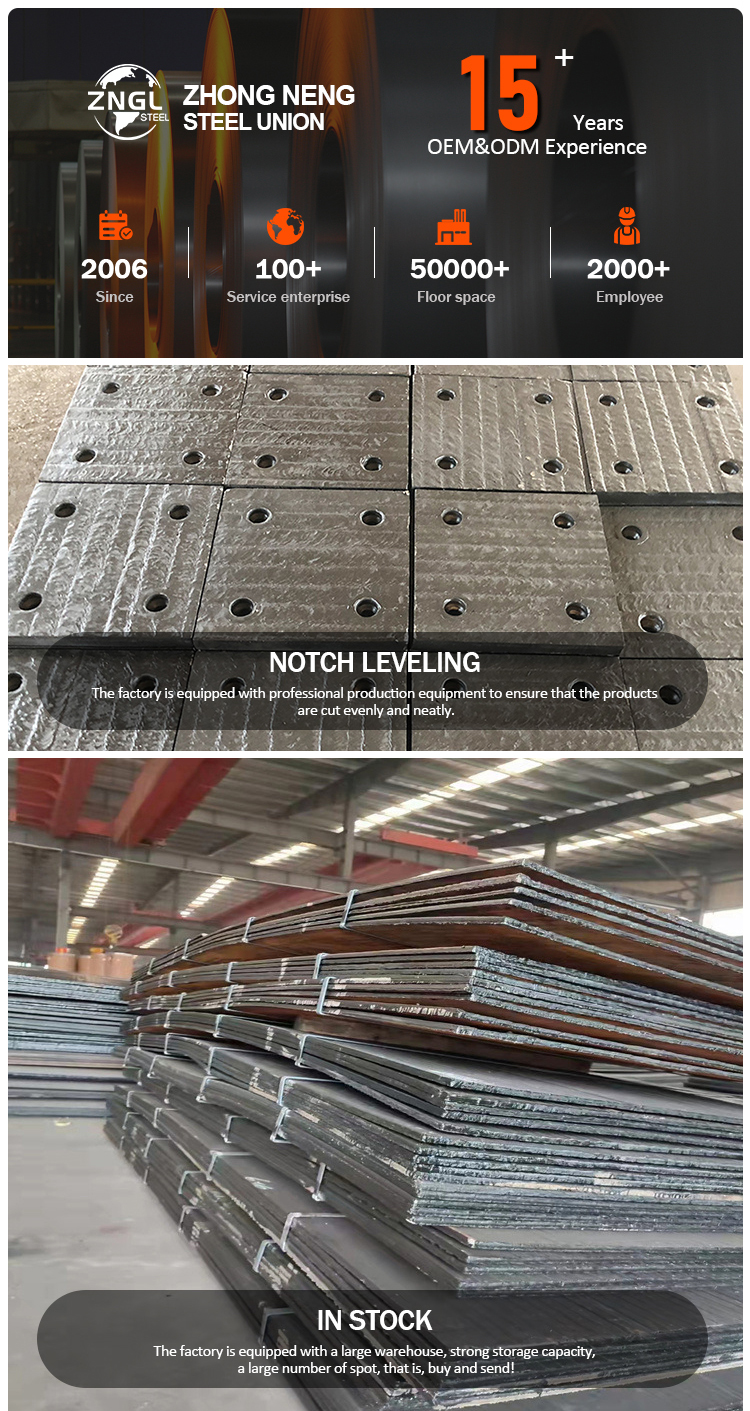

What help can we provide you?

1、Customize production size and parameter formula according to your product style.

2、Industrial experts solve the problem of industrial demand 24*7 online support.

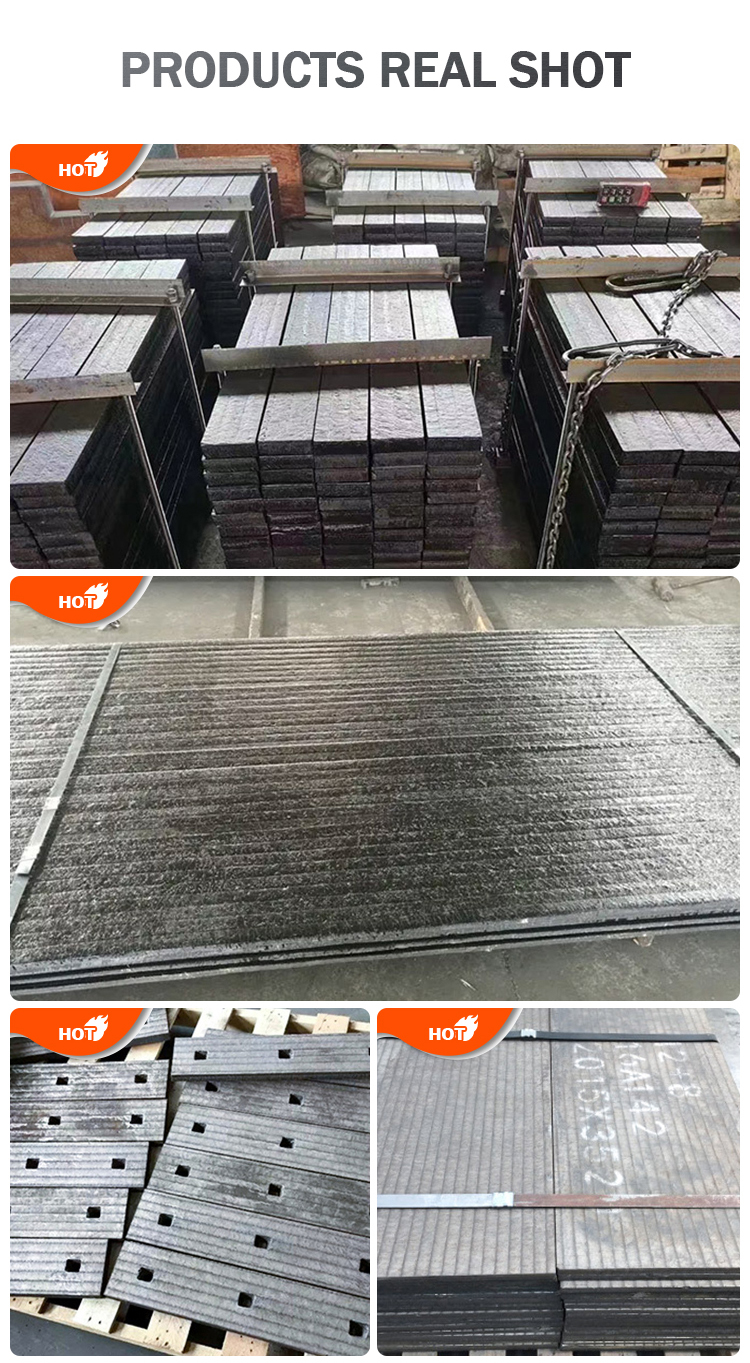

3、Video and pictures of providing actual product shooting.

4、Real factory, support friends all over the world to visit and let you feel at ease.

5、Time to track and feedback in the production link to ensure that customers understand every link of production in production.

6、Super customers can come to China to travel 2-5 times a year for free.

7、Become our customers to enjoy low prices and free samples in the industry.

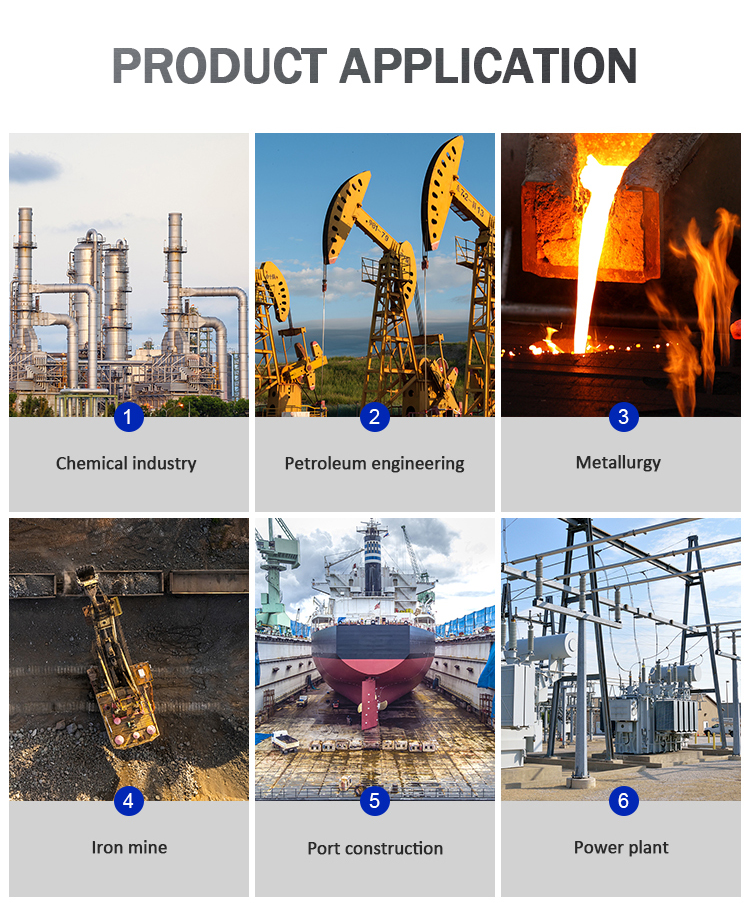

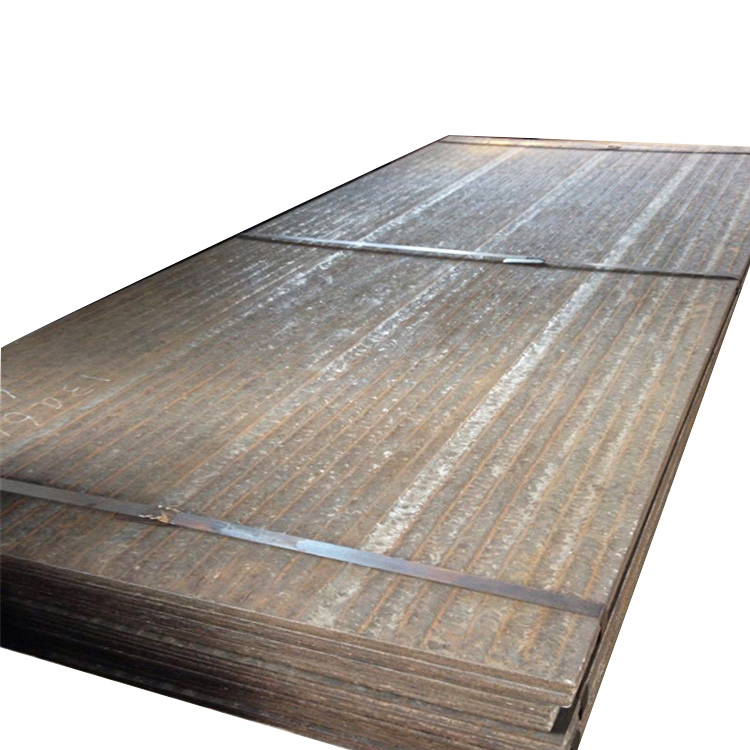

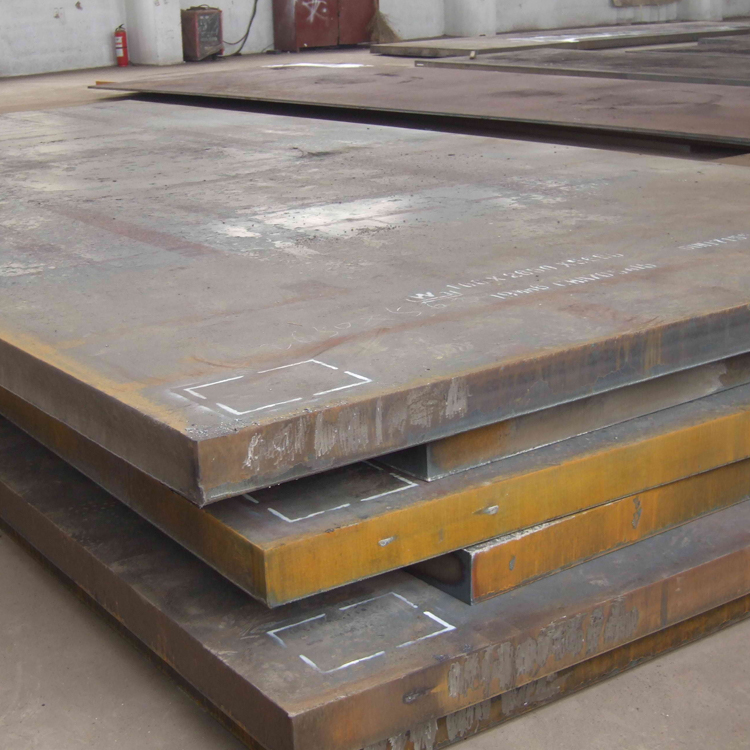

Spot Surfacing Wear Resistant Carbon Steel Plates

Product Name:Surfacing Wear Resistant Carbon Steel Plate

Brand Name:ZNGL

Alloy Or Not:Is Alloy

Delivery Time:7-30

Material:NM360 400 450 500 550 600

Surface Treatment:hardening and tempering

Edge:Mill Edge Slit Edge

Payment term:TT / LC

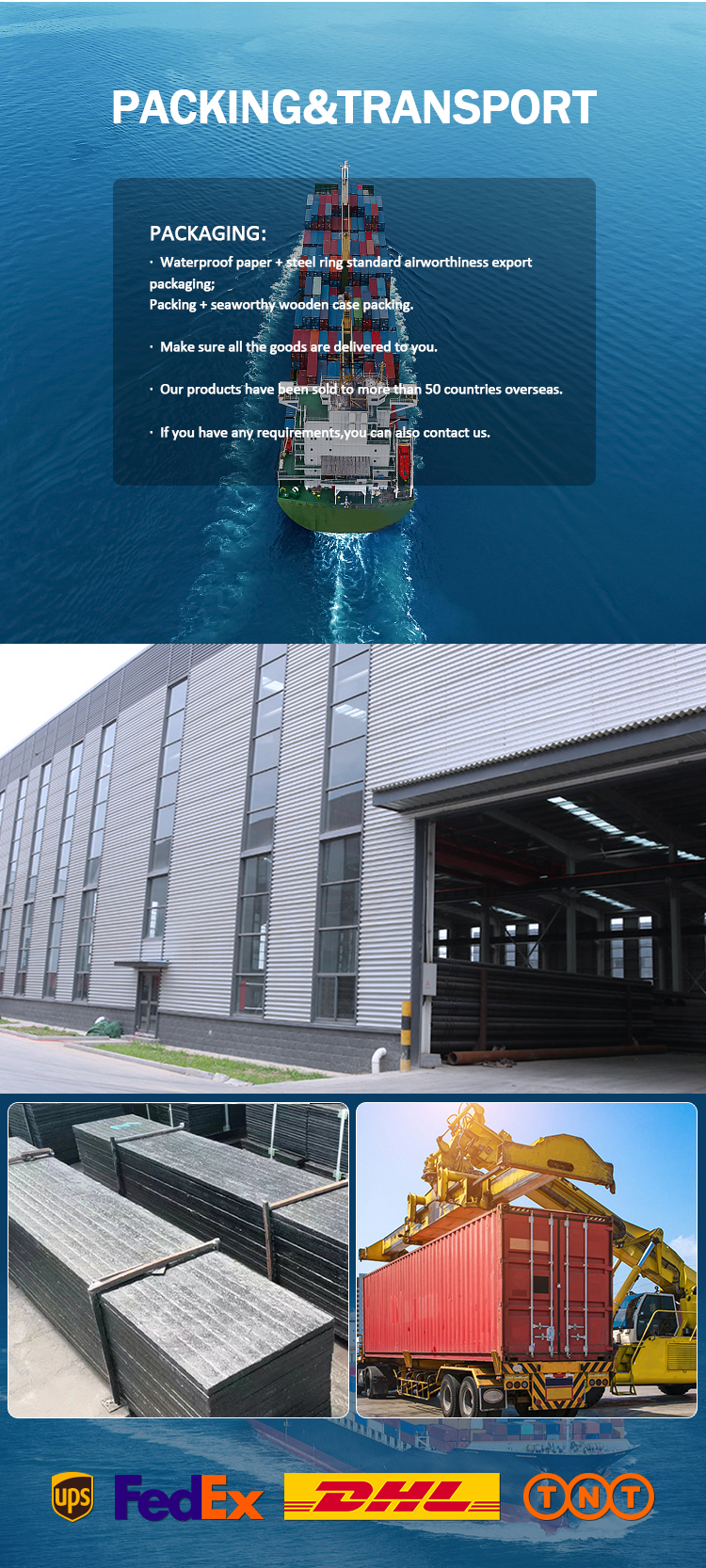

Package:Sea-worthy Package

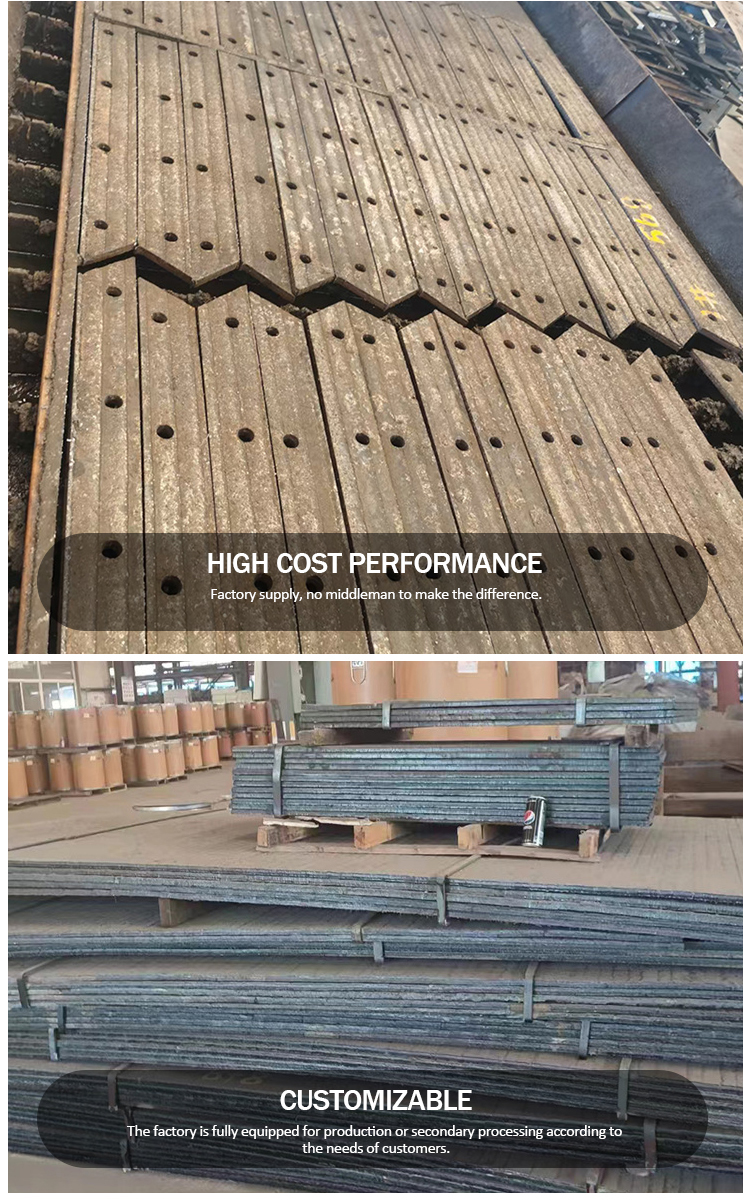

Surfacing wear-resistant plates have good thermal strength, wear resistance and impact resistance, and are suitable for high temperature environments. Hardfacing wear plates can resist tension and compression without significant bending. The surfacing wear plate has good surface quality and internal quality, and is suitable for making high-quality products.

Grade Comparison | |||||||

GB | NM300,NM360,NM400,NM450,NM500 | ||||||

SS | HARDNESS400, HARDNESS450, HARDNESS500, HARDNESS600 | ||||||

DIN | XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500 | ||||||

NBN | QUARD400, QUARD450, QUARD500 | ||||||

NF | FORA400, FORA500, Creusabro4800, Creusabro8000 | ||||||

JIS | JFE-EH360 , JFE - EH400 , JFE - EH500 , WEL-HARD400 , WELHARD500 | ||||||

SFS | RAEX400, RAEX450, RAEX500 | ||||||

Grade | |||||||

Chemical Composition ( ≤ ) | NM300 | NM360 | NM400 | NM450 | NM500 | ||

C | 0.23 | 0.25 | 0.3 | 0.35 | 0.38 | ||

Si | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | ||

Mn | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | ||

P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | ||

S | 0.015 | 0.015 | 0.01 | 0.01 | 0.01 | ||

Cr | 0.8 | 1.1 | |||||

Ni | 0.5 | 0.5 | 0.7 | 0.8 | 1 | ||

Mo | 0.4 | 0.5 | 0.5 | 0.55 | 0.65 | ||

Thickness (mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤70 | ||

Tensile strength (MPa) | ≥1000 | ≥1100 | ≥1200 | ≥1250 | -- | ||

Elongation A (%) | ≥14 | ≥12 | ≥10 | ≥7 | -- | ||

Surface Brinell hardness (HBW) | 270-330 | 330-390 | 370-430 | 420-480 | ≥470 | ||

Hardfacing wear plates have a high service life and can withstand high and low temperature environments very well. Hardfacing wear plate is an important product in the cutting tool industry, with excellent performance, it can be applied to various machinery manufacturing industries.manufacturers supplier company factory mills